ECXT-6025 3000W fiber laser cutting machine

Technical section

First, product features

The use of bilateral servo motor and guide rotation mechanism, high cutting accuracy, the use of display professional software, can be free to design a variety of graphics to carry out or text instant processing, flexible processing, simple operation, convenient. Applied to high-speed cutting, with high speed and stability.

1) Scope of application

Suitable for stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel titanium alloy, inconel alloy, titanium alloy and other metal materials.

Widely used in aerospace, automobile and ship, machinery manufacturing, elevator manufacturing, advertising production, household appliances manufacturing, medical equipment, hardware, decoration, metal external processing services and other manufacturing industries.

2) Advantages of fiber laser cutting machine

1. Excellent beam quality: the focusing spot is smaller, the cutting line is finer, the work efficiency is higher, and the processing quality is better;

2, very high cutting speed: is the same power CO2 laser cutting machine 2 times;

3, high stability: the use of the world's top fiber laser, stable performance, key components service life of up to 100,000 hours;

4. Extremely high electro-optical conversion efficiency: fiber laser cutting machine is 2 times higher than CO2 laser cutting electro-optical conversion efficiency, energy saving and environmental protection;

5, very low cost of use: the power consumption of the whole machine is only 20- of similar CO2 laser cutting machines.

30 ;

6. Extremely low maintenance cost: no laser working gas; Optical fiber transmission, no need for reflective lenses; Significant maintenance cost savings can be achieved;

7, product operation and maintenance is convenient: optical fiber transmission, no need to adjust the optical path;

8.Super flexible light guide effect: small size, compact structure, easy flexible processing requirements.

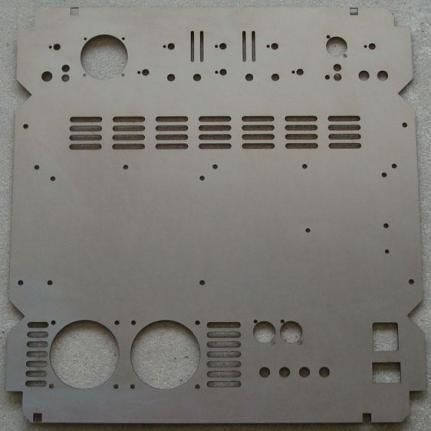

(3) Cutting sample processing renderings

Second, the equipment parameters

|

Model |

LFS6025-3000W |

|

Work area |

6050*2550 |

|

Max laser power |

3000W |

|

High adjust |

Plane tracking |

|

Minimum line width |

0.15mm |

|

Pulse frequency |

1-5000Hz |

|

Repeatability |

±0.02mm |

|

Aim for positioning |

Red light |

|

Power supply |

380V/50Hz/60Hz/100A |

|

Machine size |

7880x3450x2000mm |

Third, the main configuration

Ordinal Number Name Model/Series Quantity Manufacturer Name.

| No. |

Product name |

Model/series | Quantity | Manufacturer |

|

一 |

Laser generator | |||

|

1 |

Laser source | 3000w |

1 set |

Joint research and development |

|

二 |

External optical path and cutting head | |||

|

1 |

Laser cutting head | auto focus |

1 set |

Jiaqiang |

|

三 |

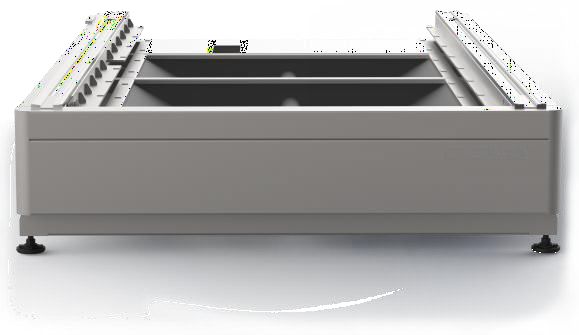

Machine tool host | |||

|

1 |

Machine bed | 6025single platform |

1 set |

Excellent Mechanical |

|

2 |

Linear Guides | HGL HA2R |

2 sets |

Taiwan KING TEK |

|

3 |

Servo motor and driver |

4 sets |

Japan Fuji |

|

|

4 |

XY axis planetary reducer | MAF-090 |

3 sets |

French Mordry |

|

5 |

Helical gear/rack | YYC 2M |

2 sets |

YYC |

|

6 |

Control cabinet |

1 set |

Excellent Mechanical | |

|

7 |

Machine tool accessories |

1 set |

Excellent Mechanical | |

|

Four |

CNC and software system | |||

|

1 |

CNC system | Bai chu |

1 set |

China Bai chu |

|

2 |

Industrial computer |

1 set |

Customized | |

|

3 |

Electrical components |

1 set |

Schneider | |

|

Five |

Standard accessories | |||

|

1 |

Precision Chiller | HL-3000 |

1 se't |

Wuhan Hanli |

|

2 |

Automatic oil filling system |

1 set |

electric |

|

|

3 |

Industrial constant temperature air conditioner |

1 set |

||

|

4 |

Exhaust system |

1 set |

pipeline reservation | |

|

5 |

Stabilizer |

1set |

customized | |

|

6 |

Receiving trolley |

1 set |

customized | |

| Six | Operational main efficiency | |||

|

1 |

Max speed | 1.2G | ||

|

2 |

Operational main efficiency | 120m/Min | ||

Fourth, the cutting process parameter table

| Material type | Thickness (mm) |

Speed (m/min) | focus position | Cuttingheight (mm) |

Gas | Nozzle Type |

Air pressure (bar) |

Laser power (W) |

cutting frequency (Hz) |

duty cycle% | cutting effect |

|

Q235B Carbon steel |

1 | 38~40 | 0~-0.5 | 0.5 | N2 | single layer1.0 | 12~16 | 3000 | 5000 | 100 | Glossy |

| 2 | |||||||||||

| 3 | 4~4.2 | 4.5~5.5 | 0.8 | O2 | double layer:1.0 | 0.6~0.9 | 3000 | 5000 | 100 | ||

| 4 | 3.3~3.5 | 4.5~5.5 | 0.8 | O2 | double layer:1.2 | 0.6~0.9 | 3000 | 5000 | 100 | ||

| 6 | 2.3~2.5 | 4.5~5.5 | 0.8 | O2 | double layer:1.2 | 0.6~0.9 | 3000 | 5000 | 100 | ||

| 8 | 2.1~2.2 | 4.5~5.5 | 0.8 | O2 | double layer:1.2 | 0.6~0.9 | 3000 | 5000 | 100 | ||

| 10 | 1.5~1.7 | 2~3 | 1.5 | O2 | double layer:3.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 |

磨砂面 |

|

| 12 | 1.2~1.4 | 2~3 | 1.5 | O2 | double layer:3.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 | ||

| 14 | 1~1.1 | 2~3 | 1.5 | O2 | double layer:4.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 | ||

| 16 | 0.85~0.9 | 2~3 | 1.5 | O2 | double layer:4.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 | ||

| 18 | 0.7~0.75 | 2~3 | 1.5 | O2 | double layer:4.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 | ||

| 20 | 0.6~0.65 | 2~3.5 | 1.5 | O2 | double layer:4.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 | ||

| 22 | 0.5~0.55 | 2~3.5 | 1.5 | O2 | double layer:4.0 | 0.6~0.9 | 2200~2400 | 5000 | 100 | ||

| 25 | 0.45~0.5 | 2~3.5 | 1.5 | O2 | double layer:5.0 | 0.6~0.9 | 2200~2500 | 5000 | 100 | ||

| SUS304

不锈钢 |

1 | 35~37 | 0~-1 | 0.5 | N2 | Single layer:1.0/1.2/1.5 | 12~16 | 3000 | 5000 | 100 | 无渣 |

| 2 | 13~15 | -1.5~-2 | 0.5 | N2 | Single layer:1.5/2.0 | 12~16 | 3000 | 5000 | 100 | ||

| 3 | 7~8 | -2.5~-3 | 0.5 | N2 | Single layer:2.0/2.5/3.0 | 16~20 | 3000 | 5000 | 100 | ||

| 4 | 4.5~5.5 | -3.5~-4 | 0.5 | N2 | Single layer:3.0 | 16~20 | 3000 | 5000 | 100 | ||

| 6 | 1.7~1.9 | -5~-5.5 | 0.5 | N2 | Single layer:3.5/4.0 | 16~20 | 3000 | 5000 | 100 | ||

| 8 | 0.8~1.0 | -6~-7 | 0.5 | N2 | Single layer:4.0 | 16~20 | 3000 | 5000 | 100 | ||

| 10 | 0.6~0.7 | -7.5~-8.5 | 0.5 | N2 | Single layer:4.0 | 16~20 | 3000 | 5000 | 100 | 少量挂渣 | |

| AL铝(6061) | 1 | 30~33 | -0.5~-1 | 0.5 | N2 | Single layer:1.0/1.2/1.5 | 12~16 | 3000 | 5000 | 100 | |

| 2 | 10~12 | -1~-1.5 | 0.5 | N2 | Single layer:1.5/2.0 | 12~16 | 3000 | 5000 | 100 | ||

| 3 | 5.5~5.9 | -2.5~-3 | 0.5 | N2 | Single layer:2.0/2.5/3.0 | 16~20 | 3000 | 5000 | 100 | ||

| 4 | 2.8~3.2 | -3.5~-4 | 0.5 | N2 | Single layer:3.0 | 16~20 | 3000 | 5000 | 100 | ||

| 6 | 0.7~0.8 | -5~-5.5 | 0.5 | N2 | Single layer:3.5/4.0 | 16~20 | 3000 | 5000 | 100 | ||

| 8 | 0.5~0.6 | -6~-7 | 0.5 | N2 | Single layer:4.0 | 16~20 | 3000 | 5000 | 100 | ||

| 黄铜 | 1 | ||||||||||

| 2 | |||||||||||

| 3 | 4.5~5 | -2~-2.5 | 0.5 | N2 | Single layer:2.0/2.5/3.0 | 16~20 | 3000 | 5000 | 100 | ||

| 4 | 3~3.5 | -3~-3.5 | 0.5 | N2 | Single layer:3.0 | 16~20 | 3000 | 5000 | 100 | ||

| 5 | |||||||||||

| 6 | 1~1.2 | -5~-5.5 | 0.5 | N2 | Single layer:3.5/4.0 | 16~20 | 3000 | 5000 | 100 | ||

| 8 | |||||||||||

| 备注 | 1,In the cutting data, the core diameter of the output fiber of the 3000W laser is 100 microns; | ||||||||||

| 2,This cutting data uses Jiaqiang cutting head, the optical ratio is 100/125 (collimation/focusing mirror focal length); | |||||||||||

| 3,Cutting auxiliary gas: liquid oxygen (purity 99.6%) liquid nitrogen (purity 99.995%); | |||||||||||

| 4,Due to the differences in equipment configuration and cutting process (machine tool, water cooling, environment, cutting gas nozzle and gas pressure, etc.) adopted by different customers, this data is for reference only. | |||||||||||

5. Machine tools and main accessories

(1)

BedThe bed adopts the patented structure of Chaoxing Group, and the overall aging stress relief treatment is completed by one-time precision machining of a large machining center to ensure high rigidity, precision and stability;

(2) Gear racks and guide rails

Rack and pinion: Taiwan precision helical rack and pinion, P-class linear guide as transmission elements, high precision and high speed.

Guide rails: Taiwan linear guides are used, and heavy-duty precision linear guides with optimized structural design are integrated. Compared with other linear guides, the load and rigidity are improved; it has the advantages of high speed, high load, high rigidity and high precision.

(2) Servo motor

Using Japanese servo motors, it has good dynamic response acceleration, and realizes the possibility of high-position positioning. High stability, high precision and maintenance-free.

(4) Reducer

Adopt imported reducer.

advantage:

High precision: backlash less than 3 arc minutes, accurate positioning.

High rigidity, high torque: The use of integral roller bearings greatly improves rigidity and torque.

No Grease Leakage: Use high-viscosity, hard-to-separate grease to effectively prevent grease leakage.

Easy maintenance: no need to change grease during the life of the product.

(5) Fiber laser generator

Choose the joint research and development fiber laser generator, the advantages of the laser generator:

▲ High electro-optical conversion rate

▲ Excellent beam quality

▲ Long service life

▲ Low cost of comprehensive use

▲ Maintenance free

6) Features of fiber laser head:

1. Adopt QBH interface, which can adapt to all fiber lasers output by QBH connector.

2. The dustproof design of the collimating protective mirror designed by the invention patent.

3. Automatic focus adjustment, fast speed, high precision and convenient operation.

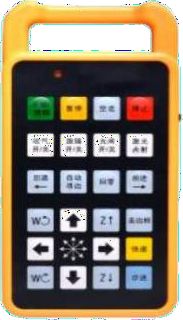

(7) Control system:

The CNC control system consists of the main components such as the PC control system, the driver and its servo motor. The special laser CNC system is adopted, which represents the most professional laser processing CNC system. The compact and modular CNC meets the needs of users using high-performance CNC systems with its good price/performance ratio.

Superior performance:

Ø First-class technology and efficiency

CNC's new technology and open CNC architecture with Intel dual-core CPUs give users more flexibility in choosing CNC parts and one-step ahead CNC performance.

Ø Modular structure

lHigh-speed machining

lHigh-speed machine tools require extremely short block cycle time (PA reaches 7200 blocks/sec) and special control algorithms and communication functions. "Adaptive pre-reading function" will pre-process 1000 blocks in real time program, and calculate the maximum feed rate within the programming parameters and limits to meet the requirements of complex machining.

Ø Accuracy

The requirements for high productivity, high precision and good surface finish quality are constantly increasing.

Ø Human-machine interface

Comprehensive diagnostic functions to quickly find faults; a variety of cutting auxiliary gases can be easily converted through the numerical control system.

It has a laser expert cutting process parameter library and a user-friendly expert library parameter interface, which can modify the laser cutting process parameters in real time in the interface.

The Ethernet communication interface can communicate directly with the computer and transfer part program files. With status display and display function of current position.

The hard disk storage space is 250G, and the processing program can be called directly from the hard disk, so it is not limited by the system memory. Remote diagnosis function, digital servo system. Color LCD display.

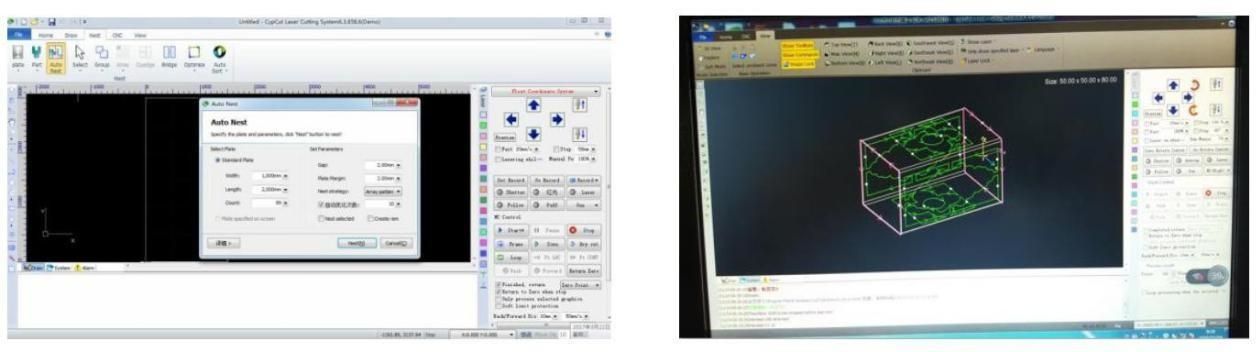

(8) Program design and nesting software

Cypcut and Cuytube is a powerful metal cutting system and intelligent typesetting software, including laser cutting process processing, common nesting functions and laser processing control. The main functions include graphics processing, parameter setting, custom cutting process editing, layout, path planning, simulation, and cutting process control.

9) Cooling system

Adopt Wuhan Hanli chiller system to cool the laser generator, efficiently cool the optical components and the cutting head. The cooling unit has a closed-loop cooling water circuit.

(10) Industrial air conditioners

High-end dedicated industrial air conditioners are used to effectively ensure clean air and ambient temperature in the cabinet, intelligent automatic control, intelligent regulation according to the ambient temperature in the cabinet, double filter protection, fully adaptable to harsh environments such as poor environment, high dust, and high temperature. Greatly improve the service life of precision electrical components.

6. Technical Services

(1) Equipment work and environmental requirements

|

No. |

Details |

|

1 |

Power supply: 100KVA |

|

2 |

Power supply requirements: (regulated power supply is recommended) Rated output voltage: 380V/50Hz Three-phase voltage stability +10 Output Voltage Regulation: <2 |

|

3 |

Compressed air supply device (an air storage tank is recommended) Volume: 0.6 m3 Rated pressure: 20 bar |

1. On-site power distribution cabinet: 380V, 50Hz, three-phase four-wire, capacity not less than 100 KVA, with short-circuit protection, etc.

2. The equipment should be installed with special grounding, and its grounding resistance should not exceed 4Ω.

3. Provide necessary lifting equipment and personnel.

4. Provide materials such as steel plates required for on-site debugging of the equipment.

5. Provide temporary pass for debugging personnel.

6. Auxiliary conditions required for the normal operation of laser cutting equipment: a. Cutting auxiliary gas (N2, O2);

b. Water-free and oil-free compressed air supply system.

7. Equipment space and foundation requirements: The foundation is concrete.

(3) Installation and training

1. Installation:

Within 30 days after the signing of the business contract, provide the user with the installation floor plan (including the requirements for the installation of civil works, water, electricity, gas, piping, interfaces, etc.).

The equipment is installed at the user's factory, and the user is required to provide sufficient space, power supply and ventilation system to install the equipment. Installation is performed by the supplier's highly trained engineers. The supplier is responsible for equipment installation (including the installation of exhaust ducts) and debugging. The user is responsible for the civil work of the equipment installation, and the water pipes, gas pipes, and power lines are connected to the machine tool designated by the supplier's engineer, and Party B is responsible for the pipeline connected to the machine tool, but the user should provide the supplier's engineer with the necessary cooperation and assistance for equipment installation and debugging.

2. Training:

The training of personnel is completed in the buyer's factory, mainly to learn equipment maintenance, operation, laser protection, processing technology, graphic editing, common troubleshooting, etc. The trainees are required to understand computer operation and have some basic knowledge of AutoCAD drawing.

(4) After-sales

1. After acceptance, the quality guarantee period of the whole machine is two years. If the parts of the system have quality problems during the warranty period, our company's well-trained service engineers will provide telephone or on-site service at any time. Phone response in 2 hours

, on-site service is within 24 hours.

2.During the warranty period of the equipment, our company is responsible for free replacement of parts and services for any damage or damage caused by the quality of the equipment itself, except for conventional consumables (such as optical lenses, nozzles) and those that are responsible for the user's illegal operation.

3.Outside the warranty period of the equipment, our company's well-trained service engineers will provide telephone or on-site service at any time. Phone response is within 2 hours and field service within 48 hours. If the replacement of spare parts is involved, our company will charge the parts cost according to the market price, and you will be responsible for the travel expenses of our company's maintenance engineers.